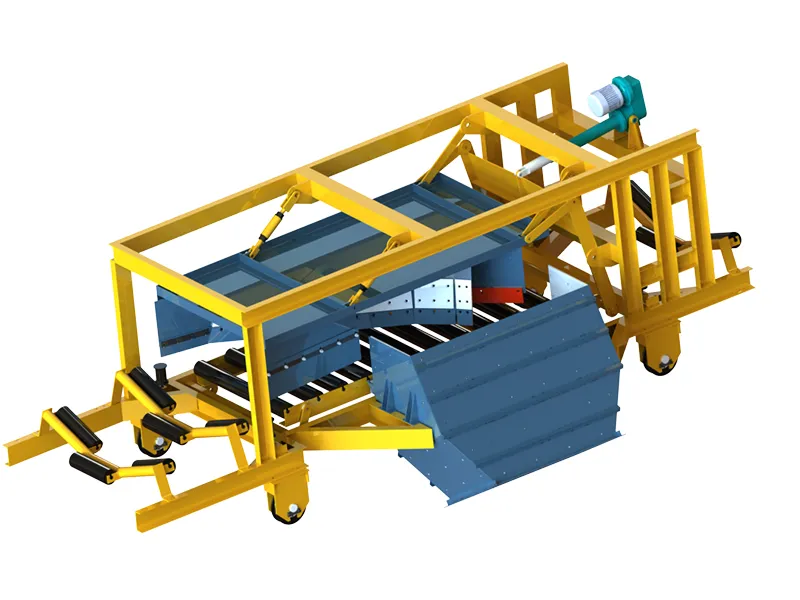

As an essential component for material handling systems, we design our tripper cars to add versatility and efficiency to conveyor operations. This movable unit is powered along tracks laid along the conveyor frame, allowing it to shuttle back and forth across the length of the conveyor. As materials are conveyed, they reach the tripper car's position and fall into its discharge hopper, enabling targeted unloading at any desired point along the conveyor. This feature is particularly useful in large-scale operations where materials need to be distributed across different areas or stored in various silos or piles, making the tripper car a vital tool for optimizing material distribution and storage strategies.

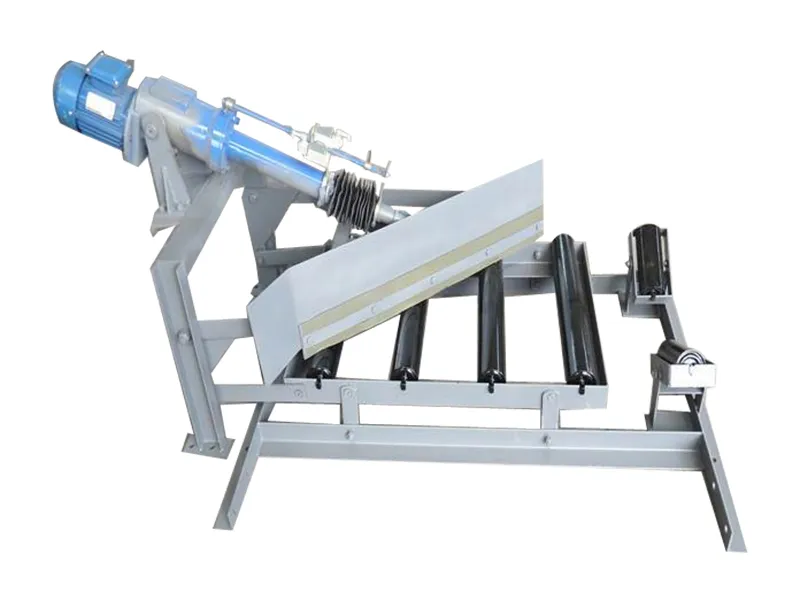

Diverter plows are devices for belt conveyors that require mid-route unloading capabilities. These plows serve as a non-terminal unloading solution, diverting materials from the main conveyor belt to alternative routes or storage areas without stopping the conveyor system. This flexibility is invaluable in operations where materials need to be distributed to various locations along the conveyor path, enhancing efficiency and optimizing material flow within the system.

The diverter plow offers a series of features that make it an indispensable part of efficient conveyor system operations, enhancing flexibility and precision in material handling.

- Allows for unloading at any desired location along the horizontal section of the belt conveyor

- Capable of distributing and unloading the same material into multiple storage bins

- Facilitates the distribution and unloading of materials into one or several specified bins

- With the use of a three-way hopper, it can achieve unloading on one or both sides of the conveyor

- Its simple design ensures easy operation

- The diverter is integrated into the conveyor line, sharing a single conveyor belt with the belt conveyor system for simple and flexible arrangement and easy maintenance

- Enables comprehensive material distribution, maximizing the use of the site for material stacking or distribution